Manual Cold Saw

Cuts steel, stainless steel, copper, brass and aluminum

S315G (12.5") S350G (14") S400G (16")

| PRODUCT | ANGLE | S315G - 315 mm (12.5") Saw Blade | S350D - 350 mm (14") Saw Blade | S400B - 400 mm (16") Saw Blade |

|---|---|---|---|---|

| round tube ⦿ | 90° | 100 mm - 3.94" | 115 mm - 4 1/2" | 130 mm - 5" |

| round tube ⦿ | 45° | 100 mm - 3.94" | 110 mm - 4 1/4" | 120 mm - 4 5/8" |

| square tube ▣ | 90° | 90 mm x 90 mm - 3.54" x 3.54" | 100 mm x 100 mm - 4" x 4" | 110 mm x 110 mm - 4 1/4" x 4 1/4" |

| square tube ▣ | 45° | 80 mm x 80 mm - 3.15" x 3.15" | 85 mm x 85 mm - 3 5/16" x 3 5/16" | 95 mm x 95 mm - 3 3/4" x 3 3/4" |

| section tube ▭ | 90° | 80 mm x 120 mm - 3.15" x 4.72" | 85 mm x 135 mm - 3 5/16" x 5 5/16" | 100 mm x 135 mm - 3 7/8" x 5 5/16" |

| section tube ▭ | 45° | 80 mm x 80 mm - 3.15" x 3.15" | 75 mm x 95 mm - 3 5/16" x 3 3/4" | 100 mm x 95 mm - 3 7/8" x 3 3/4" |

| solid round ● | 90° | 60 mm - STD 2 1/4" | 60 mm - STD 2 1/4" | 60 mm - STD 2 1/4" |

| solid square ∎ | 90° | 60 mm - STD 2 1/4" | 60 mm - STD 2 1/4" | 60 mm - STD 2 1/4" |

STANDARD FEATURES FOR S315G, S350D & S400B

- Mitering locking device stops at 45° left, straight 90°, and 45° right

- Fully integrated coolant system

- Double grip - quick action vise

- Spindle and drive unit immersed in oil solution and enclosed within gearbox housing for smooth performance and reduced machine wear.

- Included 1 HSS (high speed steel) saw blade

- (315 mm for S315G, 350 mm for S350D & 400 mm for S400B)

- S315G is for bench mount while S350D & S400B come with an integrated stand

- Trigger Switch to activate Machine

- 3 Year Mechanical Warranty

OPTIONAL EXTRAS

- Dual Arm Single Manual Vise

- Heavy Duty Conveyor with Steel Rollers (2" Diameter, 12 Gauge Rollers on 3" Centers, 12" Overall Width) 5'-0" and 10'-0" Lengths

- Feed Roller Attachments: Adjustable Heavy Duty Conveyor Stands

- Factory Fitted Broborule Kits and Length Stops

- Manual Stop System with Digital Read-out

- Pneumatic Air Vise Clamping

S315G, 350D & S400B Available In

- Single Phase, 220 Volts

- 1 Speed (54 RPM)

- 3 Phase, 220 or 460 Volts

- 2 speeds (27-54 RPM)

- 2 speeds (54-108 RPM)

- Variable Speed (27-108 RPM)

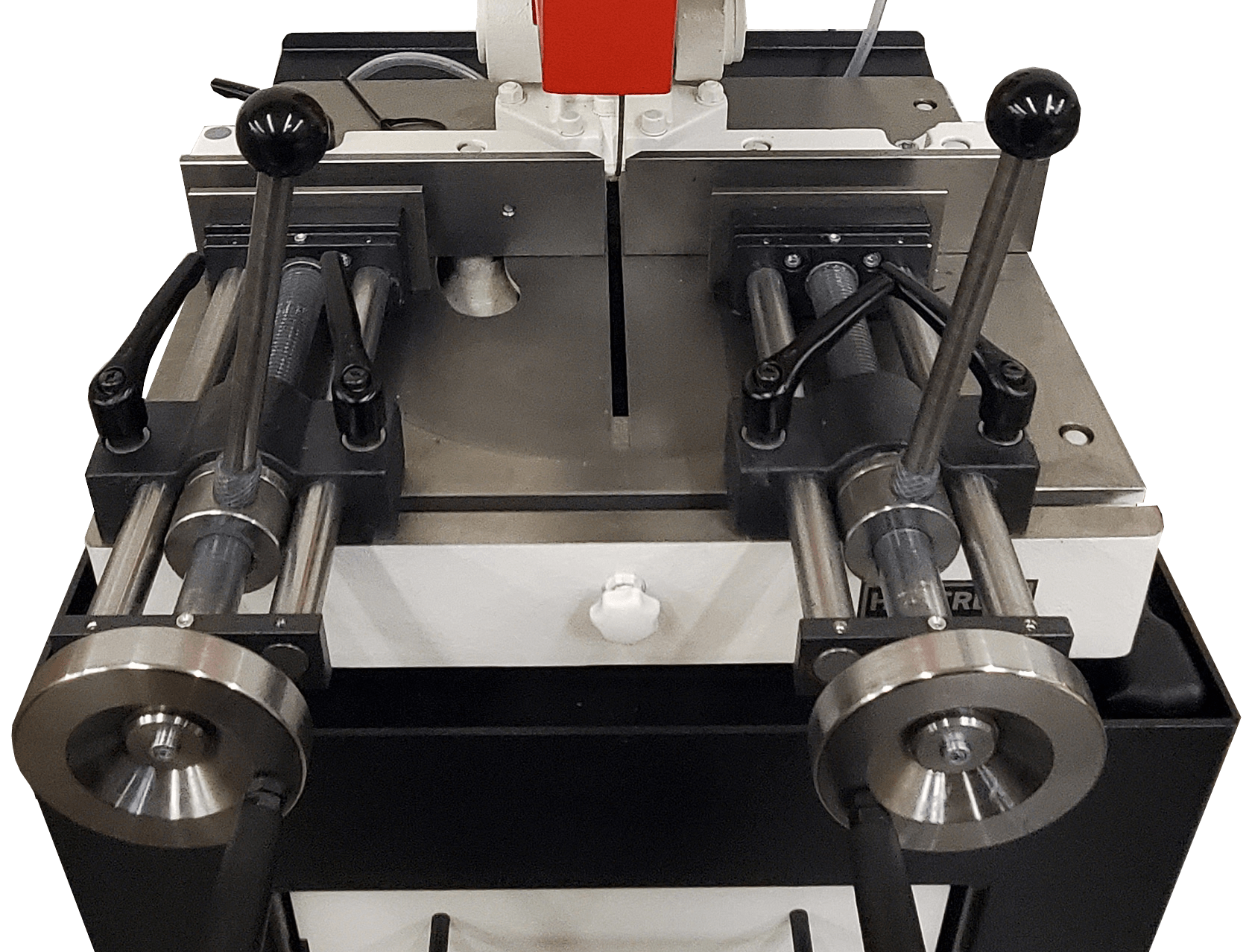

Small Compact S225 - 225mm (9")

| S225 Cutting Range | 90° | 45° | 60° |

|---|---|---|---|

| round tube ⦿ | 70 mm - 2.8'' | 65 mm - 2.6'' | 55 mm - 2.2'' |

| solid round ⬤ | 40 mm - 1.6'' | 40 mm - 1.6'' | 40 mm - 1.6'' |

| square tube ▣ | 60 mm - 2.4'' | 60 mm - 2.4'' | 50 mm - 2.0'' |

| section tube ▭ | 80 mm x 60 mm - 3.15" x 2'' | 70 mm x 50 mm - 2.8" x 2'' |

HABERLE Model S 225

HSS Saw Blade (9") 225x32mm/ Powerful saw for sites, installation and work bench. Cuts small tubes and profiles of steel, stainless steel and nonferrous metals.

Safety Saw blade Guard

Swing guided double guard of cast aluminum, covers the saw blade totally in rest position. Moving the saw head, the guard opens in the cutting area only, for best operator's safety. Quick release lift-up system to change the saw blade.

Drive Gears

Precision worm & wheel drive: Hardened and ground worm shaft. Strong main spindle runs in oil, free of maintenance. Special bronze wheel for long life. Available with standard or reduced speeds.

Available Motors & Electric

50 Hz Cycle: 1-phase 1-speed motor 230 V, 1.0 kW (1.3 HP), 3-phase 2-speed motor 400 V or 415 V, 0.8/1.2 kW (1.1/1.5 HP).

60 Hz Cycle: 1 -phase 1 -speed motor 110 V, 1.2 kW (1.5 HP), or 3-phase 2-speed motor 220 V or 460 V, 0.9/1.35 kW (1.2/1.6 HP).

Saw blade Speeds

50 Hz Cycle:

Slow speeds: 42 RPM or 42/84 RPM, allows also stainless steel.

60 Hz Cycle:

Slow speeds: 50 RPM or 50/100 RPM, allows also stainless steel.

Vise Systems

Standard with single mechanical vise. Strong buttress Ø 27 x 4 mm (1.2"). Optional: double-grip vise with replaceable jaw plates, allows burr-free straight cuts and profiled jaws for special applications. Maximum clamping range with jaw plates in place: 80 x 60 mm (3.1 x 2.4").

HSS Saw blades

225 x 2 x 32 mm (9") with 2 drive holes Ø 8 mm, cycle Ø 45 mm. A saw blades flange of Ø 70 mm allows the maximum cutting depth.

Machine Table, Pivot Bearing

Mitering table allows acute mitering to the left within 60°. Engraved 1° graduation, with quick stop bolt at 45°, strong clamp bolt M12 (1/2"). In any position, the work-piece is supported on both sides close to the saw blade. Large double yoke pivot system with 100 mm (3.9") bearing length and cast iron base care for high stability.

Innovative Saw blade Lubrication

Patented mechanical low-consumption lubrication system, specially designed to use the machine on sites and installation, cares for permanent oil supply to the saw blade without any air or electric power. A brush besides the saw blade applies pure cutting oil out of an oil cell. When starting to work, this cell has to be filled up with oil out of the 500 ccm tank by the hand operated oil pump placed on the tank. The oil cell and the capillary hose to the tank care for permanent oil lubrication for hours. Only very little oil is used up, the tank volume will last for more than 100 hours of operation. Machine, chips, material and workbench remain dry and clean. English instruction label on the tank.

HABERLE S 2000 Metal Cutting Oil

Biodegradable oil for metal cutting operations, free from mineral oils or any harmful substances, cares for a long tool life. Extremely high lubricating power leads to very poor warm up, water cooling is not necessary. S 2000 also can be used as screw-cutting oil on pipes and for other metal processing, for pure application, best for all metals.

Standard Equipment

Instruction manual in English with parts list, operating wrenches, single vise, mechanical oil lubrication system, 1 bottle with 1000 ccm cutting oil HABERLE S 2000.

Optional Equipment

Double-grip vise with jaw plates set, saw blade, cutting oil, fabricated steel stand, small length stop 1 meter (40"), graduated length stops.

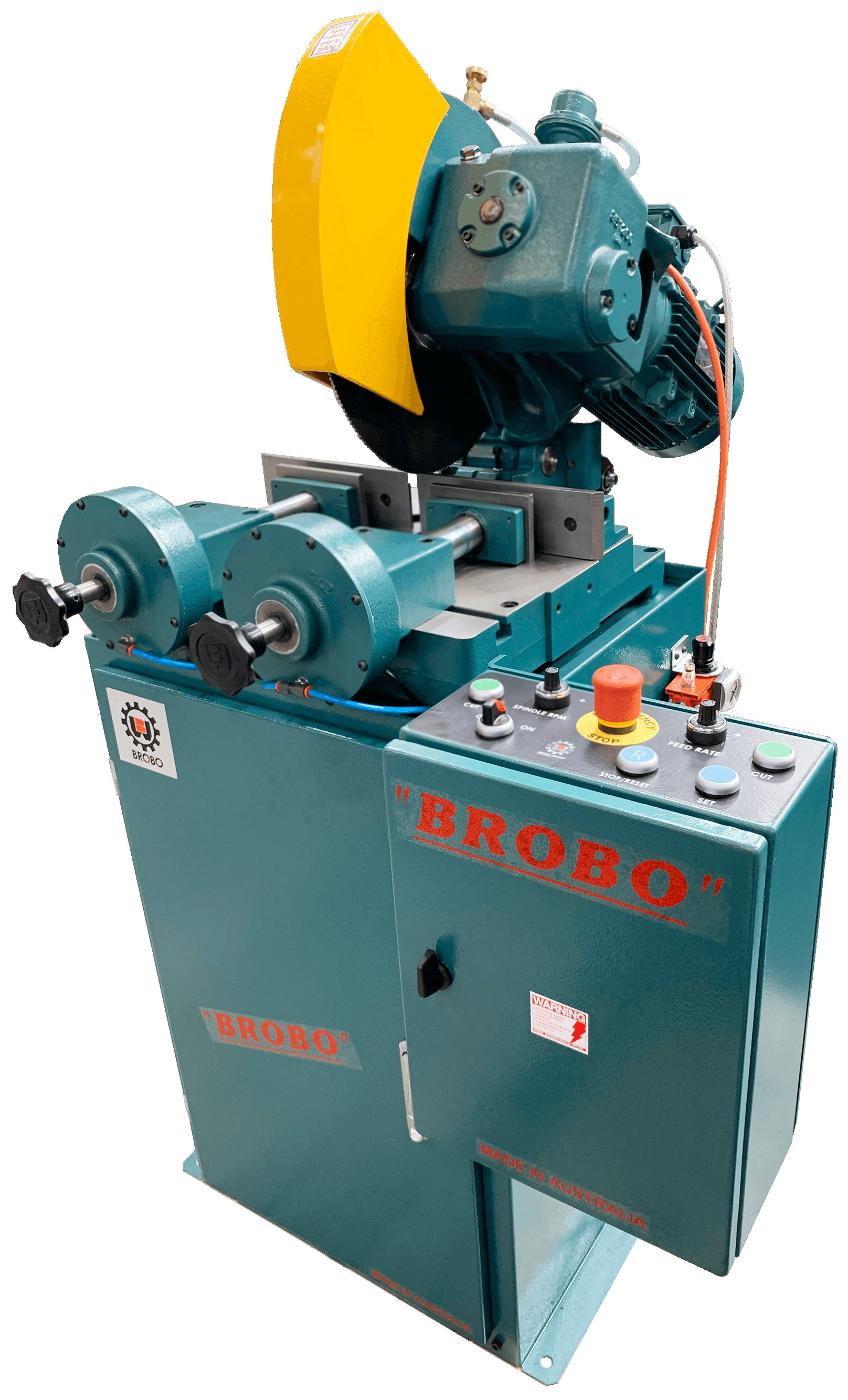

Bench Mount H300 - 315mm (12.5")

| H300 Cutting Range | 90° Straight Cut | 45° Miter Cut |

|---|---|---|

| round tube ⦿ | 95 mm - 3.8'' | 90 mm - 3.6'' |

| square tube ▣ | 95 mm - 3.75'' | 86 mm - 3.4'' |

| section tube ▭ | 160 mm x 60 mm - 6.2" x 2.5'' | 115 mm x 60 mm - 4.5 x 2.5'' |

| solid round ⬤ | 60mm - 2.5'' | 60mm - 2.5'' |

| solid square ∎ | 60mm - 2.5'' | 60mm - 2.5'' |

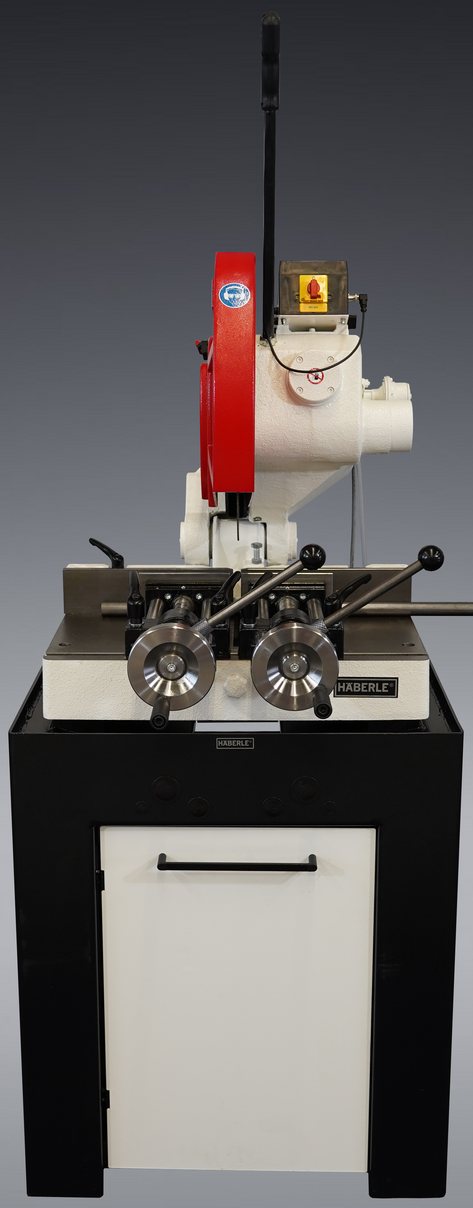

HABERLE Model H 300: HSS Saw Blade (12.5") 315x40mm/ Heavy-duty saw for material stocks, workshop and full-time production. Cuts steel, stainless steel and nonferrous metals.

Drive Gear Unit

Robust double-supported worm shaft, heavy construction saw blade drive spindle with tough texture bronze wheel.

Saw blade Speeds 50 Hz:P

Slow speed: 22.5 / 45 RPM

Single-phase: 45 RPM

Saw blade Speeds 60 Hz:

Slow speed: 26 / 52 RPM

Single-phase: 52 RPM

Clamping Unit

The strong double-grip vise allows burr-Iess straight cuts by clamping also the cut-off piece. For mitering cuts, the right arm can be taken off if necessary. Optional: Vise with quick-action lever.

Mitering 0°- 45°

The saw head turns to the left for mitering cuts.

Engraved scale 0°- 45° by 1° steps. Adjustable table clamp lever.

Air Clamping Equipment (Version B)

Optional automatically clamping vise, controlled by an air valve behind the saw head. Complete with air regulator and lubricator unit.

Vise Jaw Plates

Replaceable against specially profiled jaws if required. The rear plates can be moved to close the cutting slot for mitering cuts whenever thin material is to be cut.

Coolant Equipment

Standard with diaphragm pump, fluid regulator and handy pull-out coolant tray for perfect circulation.

Safety Saw blade Guard

Swing guided double guard of cast aluminum, swings forward without jamming vise or material and closes in rest position for safe operation.

Saw blades H.S.S.

Steam-treated, two pin-holes Ø 11 mm on circle Ø 64 mm.

315x2.5x40 mm; 300x2.5x40 mm

Main Switch

Lock-up main switch with thermal motor protection.

Weights and Dimensions

Machine unpacked: 140 kg; 750x450x900 mm

Machine packed: 155 kg; 750x550x650 mm

Standard Equipment

Double-grip vise; coolant system; operating wrenches; operator's manual with parts list.

Optional Equipment

Vise with quick-action lever; air clamping equipment; saw blades; machine stand; coolant fluid; slow-speed motor; single-phase motor; length stop; material roller carriers.

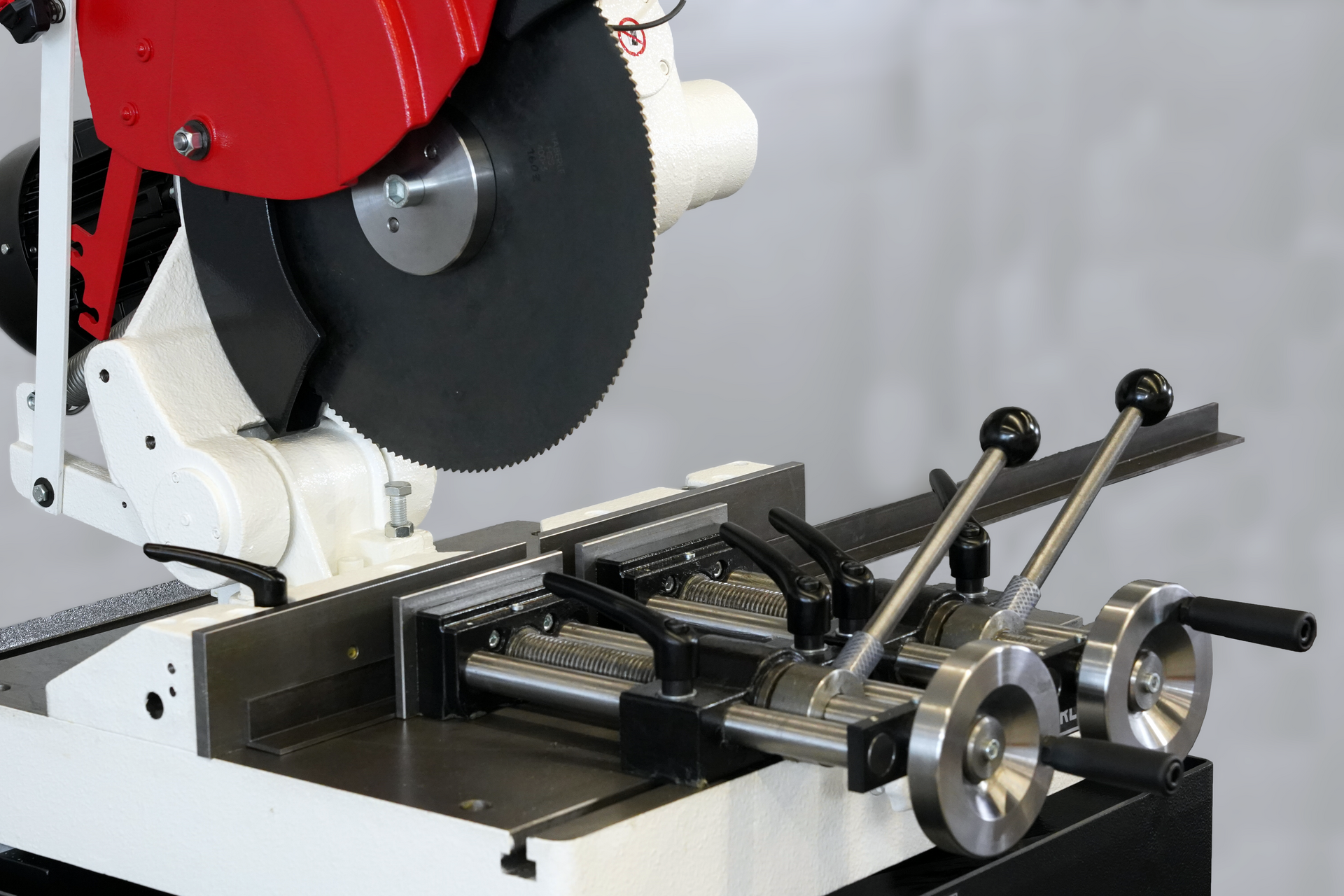

Most Popular H350 - 350mm (14")

| H350 Cutting Range | 90° | 45° |

|---|---|---|

| round tube ⦿ | 120 mm - 4.7'' | 110 mm - 4.3'' |

| solid round ⬤ | 60 mm - 2.4'' | 50 mm - 2'' |

| square tube ▣ | 105 mm - 4.1'' | 95 mm - 3.7'' |

| section tube ▭ | 160 mm x 70 mm - 6'' x 3'' | 110 mm x70 mm - 4'' x 3'' |

HABERLE Model H 350:

HSS Saw Blade (14") 350 mm x 40 mm - For workshops and full-time production, cuts steel, stainless steel, nonferrous metals.

MODEL H350 Version

A

Double-grip mechanical quick-action vise with clamp levers for quick movement to the left or right side of the saw blade. Optional second mechanical vise available if needed.

MODEL H350 Version B

Automatic double air vise system with cylinder stroke 8 mm (3/8"), pilot valve, front regulators and filter lubricator. Clamping is actuated when the saw head is moved from rest position by operator's handle. Necessary air supply: 6 bar (90 PSI).

Water coolant system with reliable high volume diaphragm coolant pump. Coolant supply to both sides of the saw blade. Removable 20 l (5 gal.) coolant reservoir, separate 20 l (5 gal.) swarf box. Quick release hose connection, fluid stop cock.

2-piece safety guard closes completely when the saw head is in rest position. Operator can not touch the saw blade. Double latch linkage for free guard movement when the head is lifted to effect the cut, outer guard remains between operator and saw blade. Quick release by spring button for easy saw blade replacement.

Oversized precision gear drive with elastic safety coupling, hardened and ground worm shaft, worm wheel of special bronze and 70 mm (2.75") dia. main spindle running in oil. Designed and built for full-time operation.

Saw blade H.S.S. max. 350x2.5x4O mm (14") with 2 drive holes 11 mm on circle 64 mm. Do not use segmental blades.

Saw blade speeds:

50 Hz:

Slow speed: 22/44 RPM also for stainless steel.

60 Hz:

Slow speed: 26.5/53 RPM also for stainless steel.

Double yoke pivot with hardened and ground shaft, adjustable on both sides.

Flat machine table with built-in precision swivel and clearly marked mitering scale. Vise remains stationary, saw head miters to any position within 45°. Positive locking by spring loaded pin at O° and 45°. Mitering table is clamped from top by clamp lever.

Jaw plates replaceable for profiled jaws. Standard rear plates movable close to the saw blade for safe cuts of thin work pieces. They reduce the cutting range for sections and structural by 12 mm (1/2").

Optional double-grip quick action vise

for burr-free straight cuts, recommended when cutting small parts. Adjustable right grip arm, vise screw with additional rear close-tolerance guide.

Optional second mechanical quick action vise

recommended on machines of version A, allows burr-free straight and miter cuts.

Dimensions & weight:

Unpacked, without operator's handle:

660x920x1500 (WxLxH 26"x36"x58")

approx. 280 kg. (615 lbs.)

3-phase motors:

Standard 50 Hz: 2-speed 0.8/1.5 kW (1.1/2.0 HP)

Standard 60 Hz: 2-speed 0.95/1.8 kW (1.3/2.4 HP)

Main switch with overload protection and emergency stop device.

Version A: Double mechanical vise, opening 240 mm, with quick adjustment sleeve.

Version B: Double air vise system with valve, front regulators and filter-lubricator.

Optional fluid spray lubricator system for pure oil lubrication at extremely low oil consumption, with the Uni-MIST® dispenser No. 20.

Featuring:

• Adjustable positive injector pump

• Adjustable pulse generator

• Pressure less oil reservoir 0.5 l (16 oz.)

• Special nozzle, adjustable to the saw blade

• Separate oil and air supply to nozzle

• Separate volume control for air and oil

• Best equipment for vegetable oil

• Pilot valve for automatic operation

• Air pressure minimum 3 bar (45 PSI)

For standard machines: Model 20/A with electrical control valve and air filter-regulator.

For machines with air vise system: Model 20/13 with air control valve.

Length stops

Standard version: 1 Meter (40") un-graduated with quick release handles. Hinged 2-piece slider to touch any position of the work piece.

Graduated versions available upon request.

Down-feed speed restriction cylinder for safe operation and longer saw blade life on the hand-operated cold saw.

Featuring:

• Quick adjustment by clamp lever

• Soft touch of the saw blade to the material

• No hook-in cutting thin-walled work pieces

• Provable longer life of saw blade

• Precision cuts as on automatic machines

• Best for untrained operators

• With air vise system a safe equipment

Free movement of the saw head towards the work piece. Adjustable trailing block cares for soft touch, pulls the piston rod of the hydraulic cylinder when cutting through the work piece and pushes back the rod when lifting back the saw head into rest position.

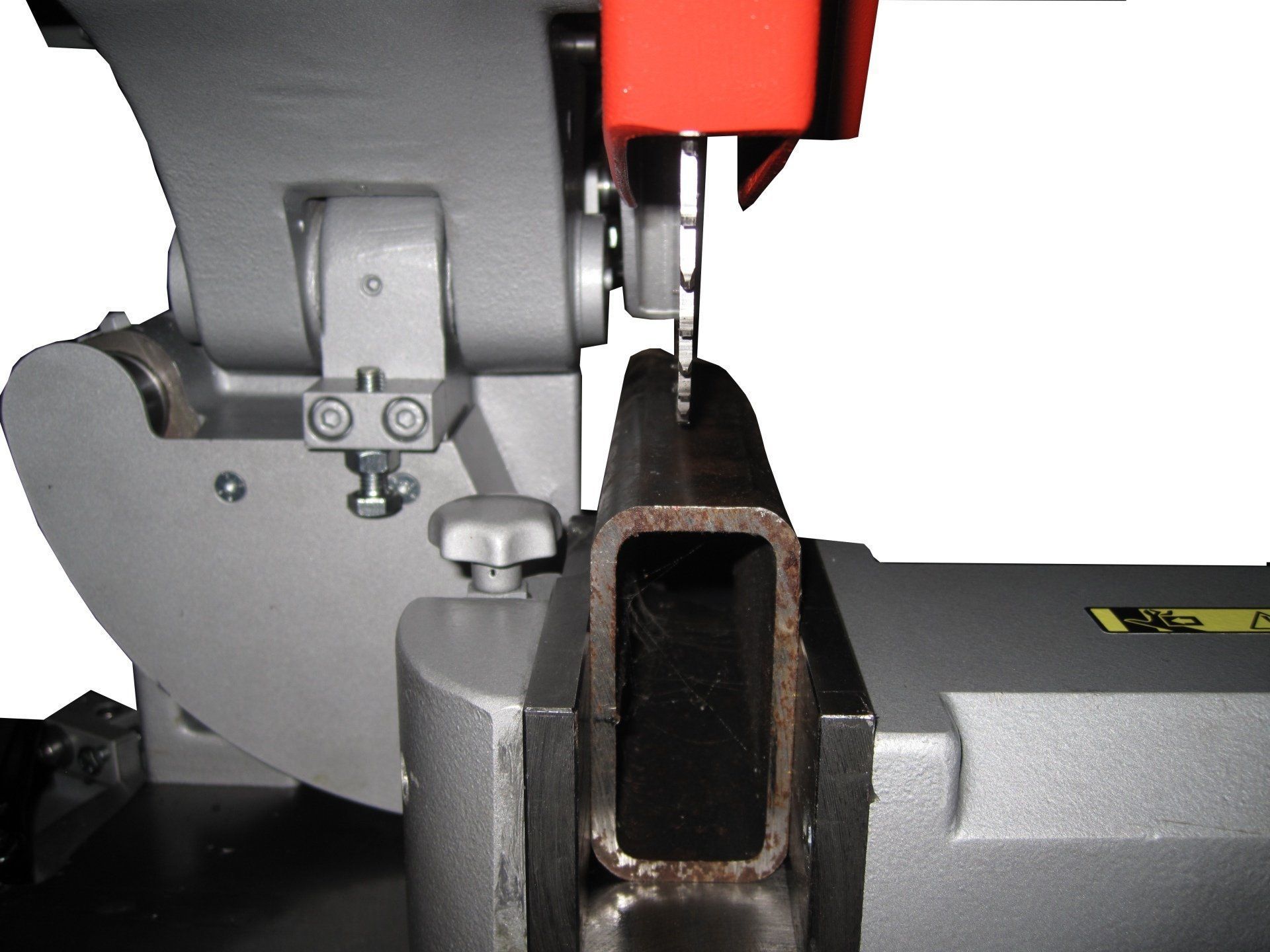

Compound Angles H90 - 350mm (14")

| H90 Cutting Range | 90° | 45° | 60° |

|---|---|---|---|

| round tube ⦿ | 115 mm - 4.5" | 110 mm - 4.3" | 100 mm - 3.9" |

| square tube ▣ | 105 mm - 4.1" | 100 mm - 3.9" | 95 mm - 3.7" |

| section tube ▭ | 108 mm x 70 mm - 7.1" x 2.8" | 160 mm x 70 mm - 6.3" x 2.8" | 120 mm x 70 mm - 4" x 2.8" |

| Channel-girder | 150 mm x 80 mm - 6" x 3.2" | 140 mm x 80 mm - 5.5" x 3.2" | 100 mm x 65 mm - 4" x 2.6" |

| solid mild steel ⬤ | 60 mm - 2.5" | 60 mm - 2.5" | 60 mm - 2.5" |

HABERLE Model H 90: HSS Saw Blade (14") 350x40mm/ Compound angel cuts, notching, angle cuts, slitting, for tubes, sections or channels of steel, stainless steel and nonferrous metals. Saw head tilts 0° - 90°

2-PIECE SAFETY GUARD of aluminum covers the whole saw blade in rest position. Multiple latch linkage with quick release knob for easy and fast saw blade replacement without removing the guards.

PRECISION WORM & WHEEL DRIVE with hardened and ground worm shaft, special bronze worm wheel and a main spindle of 70 mm (2.7") dia. running in oil. Elastic coupling between motor and gears.

TILTING SAW HEAD allows vertical mitering 0º-90º to the right side. The vise in place, it allows compound angles with tilted head 0º- 45º' and mitered vise 0º'- 60º according to the 1º- graduations. Quick adjustment by clamp levers without tools. Safe handling of the rigid moving head. Large tilting block for exact angle cuts. Double yoke pivot, adjustable.

MITERING & MOVING VISE allows horizontal angle cuts 0º- 60º. Positive lock by spring-loaded pin in straight and 45º position. To meet the total cutting range of the saw blade, the mitering vise can be moved backwards. For notching and slitting cuts, the vise can be removed and placed to the left side.

NOTCHING CUTS WITH 90° TILTED HEAD: The vise placed to the left side, the saw head can be tilted vertical up to 90º for notching cuts into channels and T-size profiles. The spring-loaded saw head movement enables exact cuts.

SLITTING CUTS IN DOOR FRAMES: The vise replaced to the left side, it allows also parallel slits by the positive 90º locking. All adjustments are done by clamp levers without tools.

MATERIAL SUPPORT BLOCK

on the left side of the table, supports the cut-off piece for safe straight and miter cuts. The block can be moved when the tilted head makes it necessary and removed to replace the vise to the left side.

SPECIAL APPLICATIONS Total altitude between table and saw blade is 210 mm (8.3") and allows various clamping

devices for many purposes, usually done on a milling machine, like slitting of bolts etc.

FREE ADJUSTABLE TURN TABLE allows always the same direction of the material feed-in. After mitering adjustment, turn the whole machine into position.

SAW BLADE SIZE H.S.S. 350x40 mm (14"); 325x40 mm (13"); 300x40 mm (12"). Two drive holes 11 mm on circle 64 mm dia. Segmental blades are not recommended, they can over stress the machine. Use the right rake angle: 16º-18º for steel and stainless steel, 22º-25º for soft aluminum alloys.

SAW BLADE SPEED AND MOTOR POWER

60 Hz: 27/54 RPM, 1.2/2.4 kW (1.7/3.3 HP)

WATER COOLANT SYSTEM with large coolant tank and chip container in the base. Reliable diaphragm coolant pump for water emulsions. Optional: Low-consumption cutting oil lubricating system or air operated oil spray system available.

ELECTRICAL EQUIPMENT 3-phase (220 V, 460 V, or 575 V), 2 speed motor. Main switch with motor protection.

AIR OPERATED VISE SYSTEM with vise cylinder 160 mm (6.3") dia., automatic stroke 8 mm (0.3"), air pilot valve, front regulator and filter-lubricator. Clamping is actuated when the saw head is moved from rest position by operating handle. necessary air supply: 6 bar (90 PSI).

DIMENSIONS AND WEIGHT (W x L x H) 700x1200x1900 mm (28"x47”x75”), approx. 320 kg.

STANDARD EQUIPMENT Grease gun, wrenches, operating manual, quick-action mechanical vise, coolant system, 24 Volt stop & go switch, 1 H.S.S. saw blade, coolant fluid

OPTIONAL EQUIPMENT Air vise system, length stop, oil lubricant systems, saw blade, coolant fluid, oil spray system.

Largest Cold Saw H450 - 450mm (18")

| H450 Cutting Range | 90° | 45° |

|---|---|---|

| round tube ⦿ | 160 mm - 6.3'' | 135 mm - 5.3'' |

| solid round ⬤ | 60 mm - 2.4'' | 60 mm - 2.4'' |

| square tube ▣ | 140 mm - 5.5'' | 120 mm - 4.7'' |

| section tube ▭ | 200 mm x 80 mm - 7.9'' x 3.2'' | 140 mm x 90 mm - 5.5'' x 3.5'' |

HABERLE Model H 450:

HSS Saw Blade (18") 450 mm x 40 mm - For steel construction and production , cuts large steel and stainless steel tubes, channels, sections and construction profiles.

Hand-operated High Quality Cold Saw

Heavy duty worm & wheel drive with hardened and ground worm shaft and special bronze worm wheel, completely free from clearance, running in an oil bath. Oversized main spindle for full-time operation, axial adjustable. Saw blade speeds: 60 Cycle = 28/56 RPM.

Safety Guard System

The two-piece hinged safety guard made of cast aluminum cares for best operator's safety. In rest position, it covers the saw blade completely and remains a short over the cutting area when swiveling the saw head. Quick lift-up without tools for easy saw blade replacement.

Saw Head Pivot System

Rigid, double yoke pivot with hardened and ground shaft, adjustable on both sides.

Mitering Saw head

Head easily miters within 45° to any position, with positive locking at 45°- 0°- 45°. Mitering table is clamped from top. Work piece remains stationary while head rotates.

Clamping System

Standard with two manual quick action vises (Version A), each movable and with exchangeable vise jaw plate. Air operated automatic vise system (Version B) at extra price, with pilot valve behind the saw head for immediate clamping when the saw head is lifted from rest position, and with air filter-regulator-lubricator. Operating pressure: 6 bar (90 PSI). Separate air regulator for each vise cylinder.

Water Coolant System

Coolant tank 40 Liters (10 Gal.); separate, removable chip container; powerful diaphragm pump driven by eccentric bearing in the saw head; coolant supply to both sides of the saw blade.

Electric Equipment

3-phase 2-speed motor, 28/56 RPM. Main switch with thermal overload protection.

Saw blades H.S.S.

450x3.5x40 mm (18")

450x3.0x40 mm (18")

400x3.0x40 mm (16")

350x3.0x40 mm (14")

350x2.5x40 mm (14")

Drive holes: 2 off 12 mm diameter on cycle 64 mm diameter.

Not recommendable for segmental saw blades, they over stress the machine.

Standard Equipment

1 set of operating tools, 1 instruction booklet with parts list.

Extra Equipment

Length stop 1 meter (40") non-graduated, various length stops with metric rule;

top clamp manual or air operated; air vise system; down feed restriction cylinder;

semi-automatic version; saw blades, coolant fluid, roller carriers.

Dimensions and Weights

Machine unpacked: 720x1000x1800 mm; 350 kg

Machine packed: 800x1200x1600 mm; 390 kg

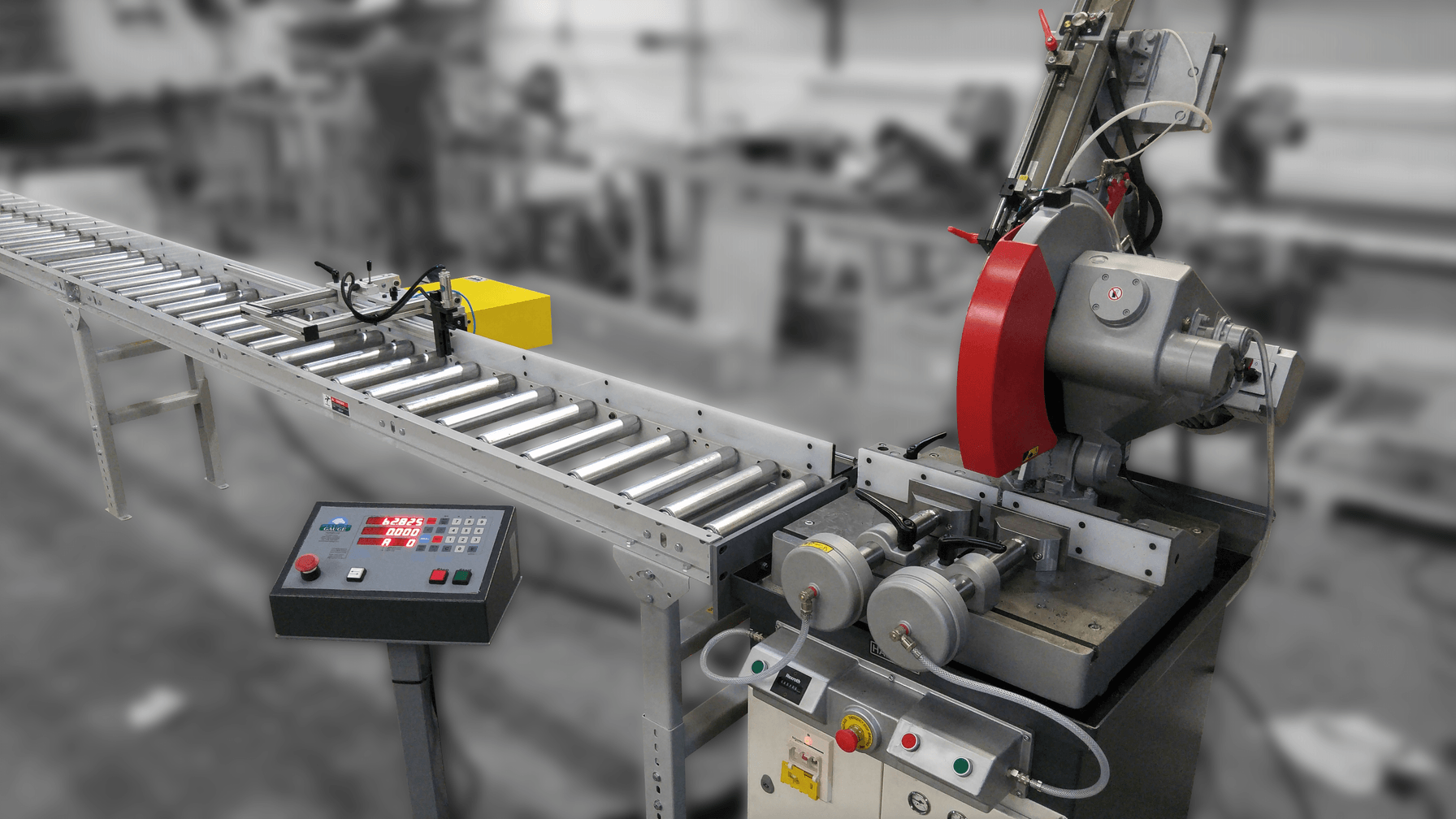

Semi-Automatic Cold Saw

Cuts steel, stainless steel, copper, brass and aluminum

Semi-Auto: SA350 (14") & SA400 (16")

STANDARD FEATURES

- Mitering locking device stops at 45° left, straight 90°, and 45° right

- Fully integrated coolant system

- Spindle and drive unit immersed in oil solution and enclosed within gearbox housing for smooth performance and reduced machine wear.

- Includes 1 HSS (high speed steel) saw blade

- (350 mm for SA350 & 400 mm for SA400)

- Saw detects the size of cutting piece and automatically sets shortest possible cutting stroke

- Active cutting load monitoring with automatic feed modulation in case of overload

- Brobolube standard lubricator

- 3 Year Mechanical Warranty

AVAILABLE IN

- Three Phase 220 V

- Variable Speed Motor (27-108 RPM)

- Three Phase 460 V

- Variable Speed Motor (27-108 RPM)

OPTIONAL EXTRAS

- Roller Conveyor with Steel Rollers ( 5' & 10' )

- Digital Length Stops ( 5', 10', 15', & 20')

- Pusher System ( Converts Semi to Fully Automatic )

Adjustable Conveyor Stands - Factory Fitted Broborule Kits and Length Stops

| PRODUCT CUTTING RANGE | ANGLE | SA350 - 350 mm (14") Saw Blade | SA400 - 400 mm (16") Saw Blade |

|---|---|---|---|

| round tube ⦿ | 90° | 115 mm - 4 1/2" | 130 mm - 5" |

| round tube ⦿ | 45° | 110 mm - 4 1/4" | 120 mm - 4 5/8" |

| square tube ▣ | 90° | 100 mm x 100 mm - 4" x 4" | 110 mm x 110 mm - 4 1/4" x 4 1/4" |

| square tube ▣ | 45° | 85 mm x 85 mm - 3 5/16" x 3 5/16" | 95 mm x 95 mm - 3 3/4" x 3 3/4" |

| section tube ▭ | 90° | 85 mm x 135 mm - 3 5/16" x 5 5/16" | 100 mm x 135 mm - 3 7/8" x 5 5/16" |

| section tube ▭ | 45° | 75 mm x 95 mm - 3 5/16" x 3 3/4" | 100 mm x 95 mm - 3 7/8" x 3 3/4" |

| solid round ● | 90° | 60 mm - STD 2 1/4" | 60 mm - STD 2 1/4" |

| solid square ∎ | 90° | 60 mm - STD 2 1/4" | 60 mm - STD 2 1/4" |

Semi-Auto: H350H (14") & H450H (18")

| Cutting Range | Angle | H350H | H450H |

|---|---|---|---|

| round tube ⦿ | 90° | 120 mm - 4.7'' | 160 mm - 6.3'' |

| round tube ⦿ | 45° | 110 mm - 4.3'' | 135 mm - 5.3'' |

| solid round ⬤ | 90° | 60 mm - 2.4'' | 60 mm - 2.4'' |

| solid round ⬤ | 45° | 50 mm - 2'' | 60 mm - 2.4'' |

| square tube ▣ | 90° | 105 mm - 4.1'' | 140 mm - 5.5'' |

| square tube ▣ | 45° | 95 mm - 3.7'' | 120 mm - 4.7'' |

| section tube ▭ | 90° | 160 mm x 70 mm - 6'' x 3'' | 200 mm x 80 mm - 7.9'' x 3.2'' |

| section tube ▭ | 45° | 110 mm x 70 mm - 4'' x 3'' | 140 mm x 90 mm - 5.5'' x 3.5'' |

HABERLE Model H 350/H (Semi Automatic):

HSS Saw Blade (14")

350 mm x 40 mm - Production saw with automatic down feed . Powered saw head with quick forward motion, adjustable power stroke and quick return. Pneumatic control system with two air vises, tow-hand safety start and emergency stop.

SAFETY GUARD

2-piece cast aluminum guard system for best operator's safety. The link operated forward section provides for maximum operator's safety and allows easy and quick saw blade replacement.

DRIVE GEARS

Extremely robust worm & wheel drive with hardened and ground worm shaft, special bronze worm wheel and a saw blade drive shaft of Ø 70 mm, running in an oil bath, for 3-shifts operation, free of maintenance. Elastic coupling between motor and drive gears.

AUTOMATIC DOWN-FEED SYSTEM

Standard with reliable DRUMAG feeder HPE-11: Quick motion from rest position to the adjustable material level and infinitely adjustable power down-feed motion, with adjustable return point and quick return motion into the upper rest position. This version allows the feeding of the material over the vise into the cutting area, but requires two-hands safety start system.

Optional with DRUMAG feeder HPE-77: This unit allows the adjustment of the upper stop position by elimination of the quick down-feed motion towards the material. This means a shorter cutting time. The one-hand start gets the feeding time down to an absolute minimum. So quantities of 200 - 300 cuts per hour can be realized when cutting tubing of Ø 50 mm.

PIVOT SHAFT

Double joke pivot system with hardened and ground shaft, adjustable on both sides. Low pivot level cares for extremely little vibration.

MACHINE TABLE

Large, plain table allows individual positioning if the two vise units. Mitering table for horizontal mitering of the saw head within 45° to both sides. Movable rear jaws allow a small cutting slot for easy and accurate straight and mitering cuts through thin-walled material.

A length stop can be installed at both sides of the back fences using the adapter hole Ø 18 mm.

SAW BLADES

H.S.S. or H.S.S.-E (Cobalt alloyed), steam treated.

350 x 2.5 x 40 mm

325 x 2.5 x 40 mm

315 x 2.5 x 40 mm

300 x 2.5 x 40 mm

Drive holes: 2 off Ø 11 mm on cycle Ø 64 mm.

Segmental blades are not recommended, they can over stress the machine.

3-PHASE MOTOR

Slow-speed USA, 60 Hz: 850/1700 RPM, 1.3/2.4 kW

SAW BLADE SPEEDS

Slow-speed motor: 22/44 RPM, USA: 27/54 RPM.

SAW BLADE LUBRICATION SYSTEMS

Water coolant system with diaphragm pump, stop cock and large containers for coolant fluid and swarf chips.

Also available: Additional low-consumption oil spray mist system with precision dispenser from UNIST Inc., USA, recommended for cutting thinner tubes, sections and rectangular profiles.

AIR VISE

Strong double-grip air vise with adjustable guide rails and adjustable arm bracket to hold the cut-off piece, for burr-free finished cuts. Replaceable vise jaws allow the installation of profiled jaws for special applications.

CONTROL SYSTEMS

For a minimum of maintenance and service, the electric system is held at the necessary minimum, including main switch, overload switches and 24 Volt circuit to watch the air control system.

The automatic cycle of clamping and down-feed is completely air controlled, including the Emergency Stop button which locks the vise cylinder in any emergency situation, and with selective switch for permanent or stop & go motor drive.

A control desk incorporates the manual actuators (Start / Stop / Emergency Stop), a cycle counter and an air coupling to install the air hose of the vise cylinder.

Operating pressure for the air supply: 6 bar.

DIMENSIONS AND WEIGHTS

Machine unpacked: 550x1000x1900mm,350kg

Machine packed: 800 x 1200 x 2200 mm, 380 kg

STANDARD EQUIPMENT

Maintenance tools, operating wrenches.

English manual with parts list.

OPTIONAL EQUIPMENT

Pusher system integrated to Automate the cutting process.

HABERLE Model H450H (Semi Automatic):

HSS Saw Blade (18") 450 mm x 40 mm - Production saw with automatic down feed . Powered saw head with quick forward motion, adjustable power stroke and quick return. Pneumatic control system with two air vises, tow-hand safety start and emergency stop.

SAFETY GUARD

2-piece cast aluminum guard system for best operator's safety. The link operated forward section provides for maximum operator's safety and allows easy and quick saw blade replacement.

DRIVE GEARS

Extremely robust worm & wheel drive with hardened and ground worm shaft, special bronze worm wheel and a saw blade drive shaft of Ø 70 mm, running in an oil bath, for 3-shifts operation, free of maintenance. Elastic coupling between motor and drive gears.

AUTOMATIC DOWNFEED SYSTEM

Standard with reliable DRUMAG feeder HPE-11: Quick motion from rest position to the adjustable material level and infinitely adjustable power down-feed motion, with adjustable return point and quick return motion into the upper rest position. This version allows the feeding of the material over the vise into the cutting area, but requires two-hands safety start system.

Optional with DRUMAG feeder HPE-77: This unit allows the adjustment of the upper stop position by elimination of the quick down-feed motion towards the material. This means a shorter cutting time. The one-hand start gets the feeding time down to an absolute minimum. So quantities of 200 - 300 cuts per hour can be realized when cutting tubing of Ø 50 mm.

PIVOT SHAFT

Double joke pivot system with hardened and ground shaft, adjustable on both sides. Low pivot level cares for extremely little vibration.

MACHINE TABLE

Large, plain table allows individual positioning if the two vise units. Mitering table for horizontal mitering of the saw head within 45° to both sides. Movable rear jaws allow a small cutting slot for easy and accurate straight and mitering cuts through thin-walled material.

A length stop can be installed at both sides of the back fences using the adapter hole Ø 18 mm.

SAW BLADES

H.S.S. or H.S.S.-E (Cobalt alloyed), steam treated.

450 x 3.5 x 40 mm

350 x 2.5 x 40 mm

Drive holes: 2 off Ø 11 mm on cycle Ø 64 mm.

Segmental blades are not recommended, they can over stress the machine.

3-PHASE MOTOR

Slow-speed USA, 60 Hz: 850/1700 RPM, 1.3/2.4 kW

SAW BLADE SPEEDS

Slow-speed motor: 22/44 RPM, USA: 27/54 RPM.

SAW BLADE LUBRICATION SYSTEMS

Water coolant system with diaphragm pump, stop cock and large containers for coolant fluid and swarf chips.

Also available: Additional low-consumption oil spray mist system with precision dispenser from UNIST Inc., USA, recommended for cutting thinner tubes, sections and rectangular profiles.

AIR VISE

Strong double-grip air vise with adjustable guide rails and adjustable arm bracket to hold the cut-off piece, for burr-free finished cuts. Replaceable vise jaws allow the installation of profiled jaws for special applications.

CONTROL SYSTEMS

For a minimum of maintenance and service, the electric system is held at the necessary minimum, including main switch, overload switches and 24 Volt circuit to watch the air control system.

The automatic cycle of clamping and down-feed is completely air controlled, including the Emergency Stop button which locks the vise cylinder in any emergency situation, and with selective switch for permanent or stop & go motor drive.

A control desk incorporates the manual actuators (Start / Stop / Emergency Stop), a cycle counter and an air coupling to install the air hose of the vise cylinder.

Operating pressure for the air supply: 6 bar.

STANDARD EQUIPMENT

Maintenance tools, operating wrenches.

English manual with parts list.

OPTIONAL EQUIPMENT

Pusher system integrated to Automate the cutting process

Pusher With Semi-Automatic Cold Saw