Aluminum Cutting Saw

(Non-Ferrous Materials)

AL380 -380mm (15") Saw Blade

Manual Aluminum Cutting Saw - 380mm (15") Saw Blade

| AL380 Cutting Range | 90° | 45° |

|---|---|---|

| round tube ⦿ | 5.5'' | 4.7'' |

| solid round ⬤ | 3" | 3" |

| square tube ▣ | 4.9" | 4.2" |

| section tube ▭ | 7'' x 3.5'' | 5'' x 3.5'' |

Carbide tipped (T.C.T.) (15") 380x40mm - High speed aluminum saw, for workshops and production, cuts aluminum alloys and plastics

Model A: Two Mechanical Push & Clamp Vises With Oil Pump

Model B: Double Air Vise System w/ Stand and UNIST Oil Mist System.

HIGH-SPEED CIRCULAR SAW FOR ALUMINUM AND PLASTIC

For cutting tubes and profiles of soft aluminum alloys and plastics (ferrous material)

*Not suitable for cutting steel, stainless steel and hard materials (ferrous material)

Standard

Both model A & B come with stand and trigger switch in the handle

3-phase Electric System:

50 Hz Currency:

Main switch, with thermal overload protection, in Europe with under voltage trip and 24 V trigger switch as shown.

3 phase 1 - speed motor 40OV, 3.0 kW, motor brake.

60 Hz Currency (USA):

Main switch, thermal overload protection, for with under voltage, trip. Optional: 24 V trigger switch in the handle.

3 phase 1 - speed motor 220/440 V or 575 V, 4.8 HP

High Speed Saw Head:

Triple belt drive to the saw blade. Strong main spindle. Hardened and ground pivot shaft, adjustable, with bronze bushes. Pivot block with chip chute channel.

Machine Table:

Large table (620 mm), miters through 45º to both sides. Spring-loaded bolt for 0º and 45º.

Saw blade Size:

Max 380 mm x 40 mm (15") TCT (tungsten carbide tipped)

Drive holes: 2x Ø12 mm on circle Ø 64 mm.

Saw blade Speeds:

3000 RPM for TCT (tungsten carbide tipped) saw blades only

Saw blade Oil Lubricating Systems:

Model A comes standard with mechanical oil pump built into the saw head. Optional with uni-MAX™ spray system from UNIST INC, USA, and

Model B comes with the UNIST spray system (spray nozzle built into the saw blade guard, adjustable to the saw blade size.)

Safety Saw Blade Guard:

Entirely closing 2-piece aluminum guard. Link-operated lift-up system, for best protection and fast saw blade replacement.

Model B:

Air vise system, automatically operated by an air valve when the saw head is lifted from rest position. Cylinder Ø 70 mm, safety stroke 8 mm (1/4'). Standard with filter regulator-lubricator. Optional with separate pressure regulators for each cylinder, installed in the machine stand. Required air supply: 6 bar (90 PSI).

AL380H - Semi Auto 380mm (15")

Semi-Automatic Aluminum Cutting Saw

| AL380H Cutting Range | 90° | 45° |

|---|---|---|

| round tube ⦿ | 5.5'' | 4.7'' |

| solid round ⬤ | 3" | 3" |

| square tube ▣ | 4.9" | 4.2" |

| section tube ▭ | 7'' x 3.5'' | 5'' x 3.5'' |

HABERLE Model AL 380H (Semi Automatic):

TCT (tungsten carbide tipped) 380 mm x 40mm saw blade (15")

- High speed aluminum saw, for high production, cuts aluminum alloys and plastics (non-ferrous)

*Not suitable for cutting steel, stainless steel and hard materials (ferrous material)

- Powered Saw head with Quick Forward Motion

- Adjustable Power Stroke and Quick Return

- Pneumatic Control System with 2-Vises

- Two-Hand Safety Start and Emergency Stop

Electric System

Main switch according to EN 262, switches off the whole machine, Thermal overload motor protection. 24 Volt system. Permanent motor drive with manual stop function.

3-phase motor 3.0 (3.6) kW, with separate switch for safe set-up or maintenance works. Available: 4.0 (4.8) kW at extra charge. Safety control system

Air controlled cutting cycle for reliable operation and easy maintenance. Two-hands safety start and emergency stop push button according to the latest safety regulations. The emergency stop signal switches off the motor and also cares for safe clamping of the material while the saw head returns into rest position.

Saw Head Down feed

Reliable saw blade feeder system with quick motion, infinitely adjustable power feed and quick return into rest position. Necessary air supply: 6 bar (90 psi).

Clamping System

Two quickly adjustable sleeve-type air vises can be moved into any position on the flat table Separate air pressure regulator for each cylinder (Ø70 mm). Replaceable jaw plates allow also profiled jaws for special applications The rear jaw plates can be moved close to the saw blade for cutting thin material.

Carbide Tipped Saw Blade

Max

380 mm x 40 mm (15") TCT (tungsten carbide tipped)

Drive holes: 2x Ø12 mm on circle Ø64 mm.

Saw Blade Lubrication

Standard with fluid spray dispenser uni-MAX® Model 20 from UNIST INC. USA, With HABERLE saw blade nozzle built into the saw blade guard, adjustable to the size of the saw blade, for best lubrication at extremely low fluid consumption.

Chip Chute Channel

The turbo-wind effect of the saw blade blows most of the chips through the channel of the pivot block, 4" diameter exhaust connection.

Optional

Pusher system integrated to Automate the cutting process

Machine unpacked:

0.8 x 1.3 x 1.6 m (2.5' x 3.6' x 5'), 360 kg

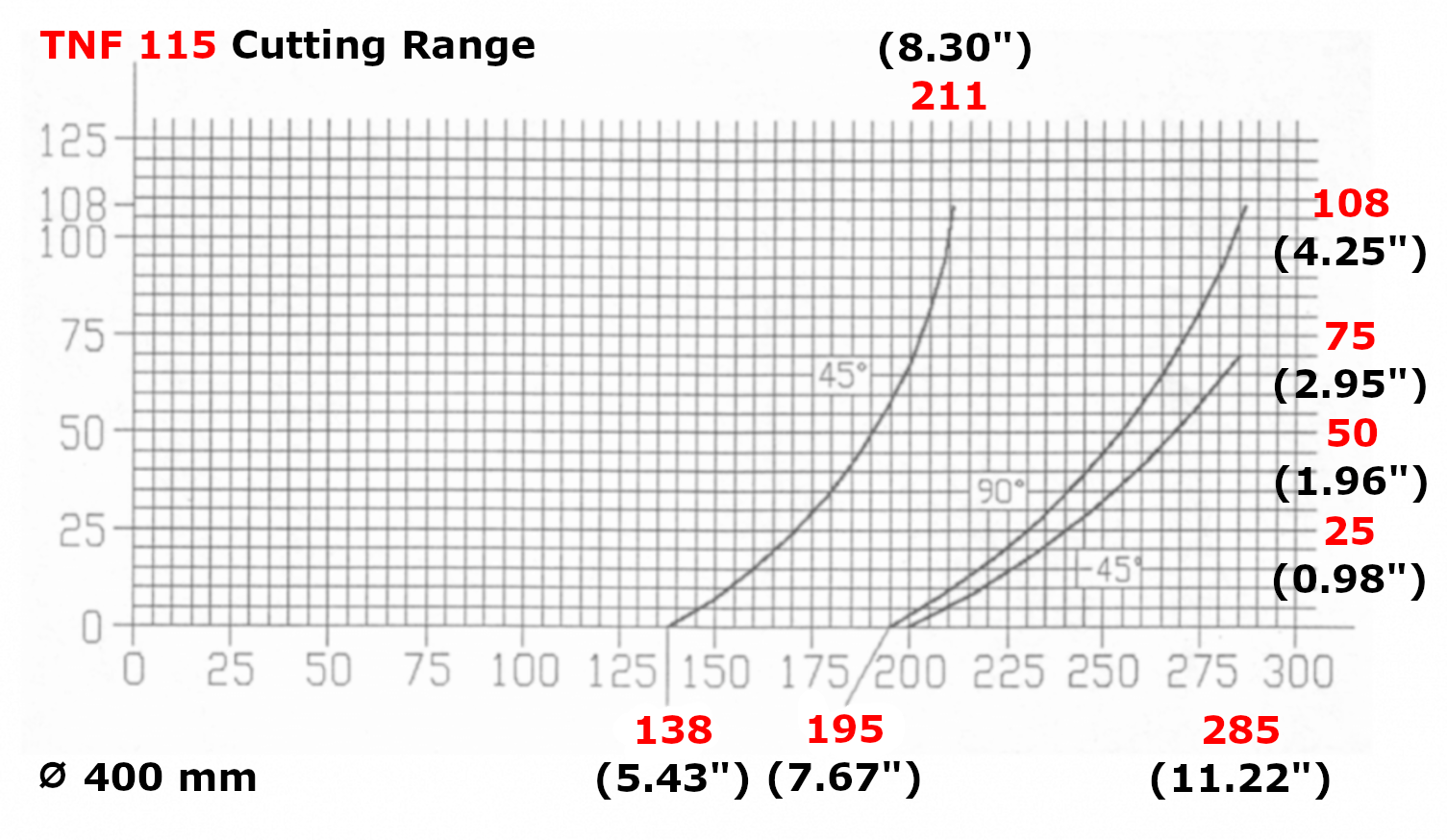

TNF 115 - 400mm (16") Saw Blade

STANDARD FEATURES

- Mitering 45° left, straight 90° and 45° right with rapid adjustment bumpers

- 45° Compound Mitering

- Vertical and horizontal pneumatic clamping

- Includes 1 400 mm (16") TCT saw blade

- spins at 4800 RPM

- Two feed roller conveyors (3m long each).

- 3m Adjustable length stop

- Trigger Switch to activate the machine

Available Power:

- 220 V Three Phase

- 460 V Three Phase

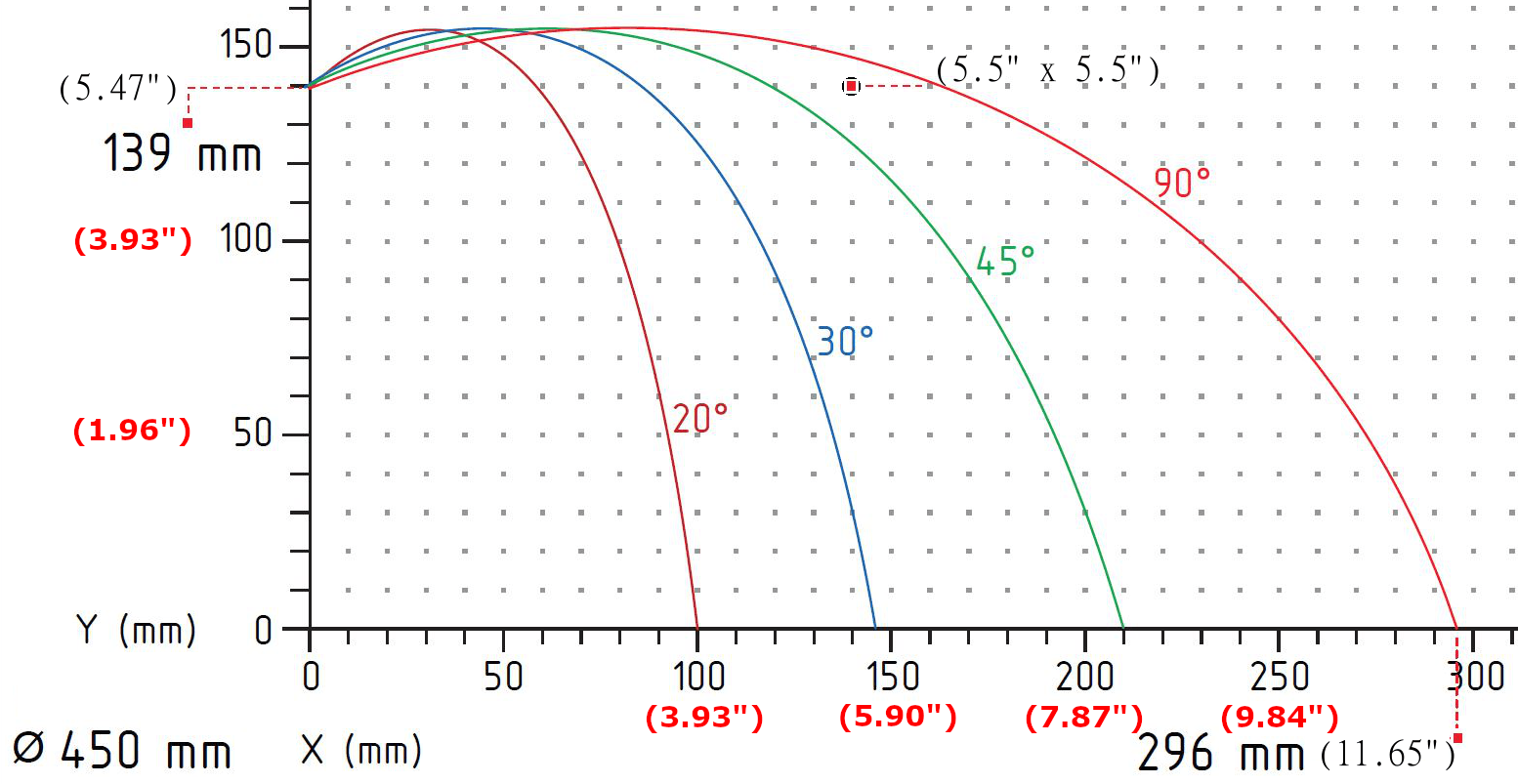

TNF 125 - Semi Auto 450mm (18")

STANDARD FEATURES

- Up-cut Saw

- Extreme Mitering 80° left, straight 90° and 80° right

- rapid adjustment bumpers

- Adjustable cutting speed

- Vertical pneumatic clamping

- Fully enclosed lid/guard with protective power supply shut down

- Power source protects against abrupt changes in voltage

- Saw exit speed regulator brings down speed in aluminum cutting, thus enables decreasing engine load

- Includes 1 450 mm (18") TCT saw blade

- rotates AT 3200 RPM

Two feed roller conveyors (3m long each)